Graphene Boosts Perovskite Solar Cell Efficiency to 30.6% in Australia

Researchers in Australia have made a significant advancement in solar technology by incorporating graphene into perovskite solar cells, achieving an impressive efficiency of 30.6 per cent while reducing reliance on costly gold and silver conductors.

This discovery emerged from a collaboration between Halocell Energy, a company specialising in perovskite cells, and the Queensland University of Technology (QUT), which was established in 2023 to commercialise this innovative technology.

Innovative Manufacturing Techniques

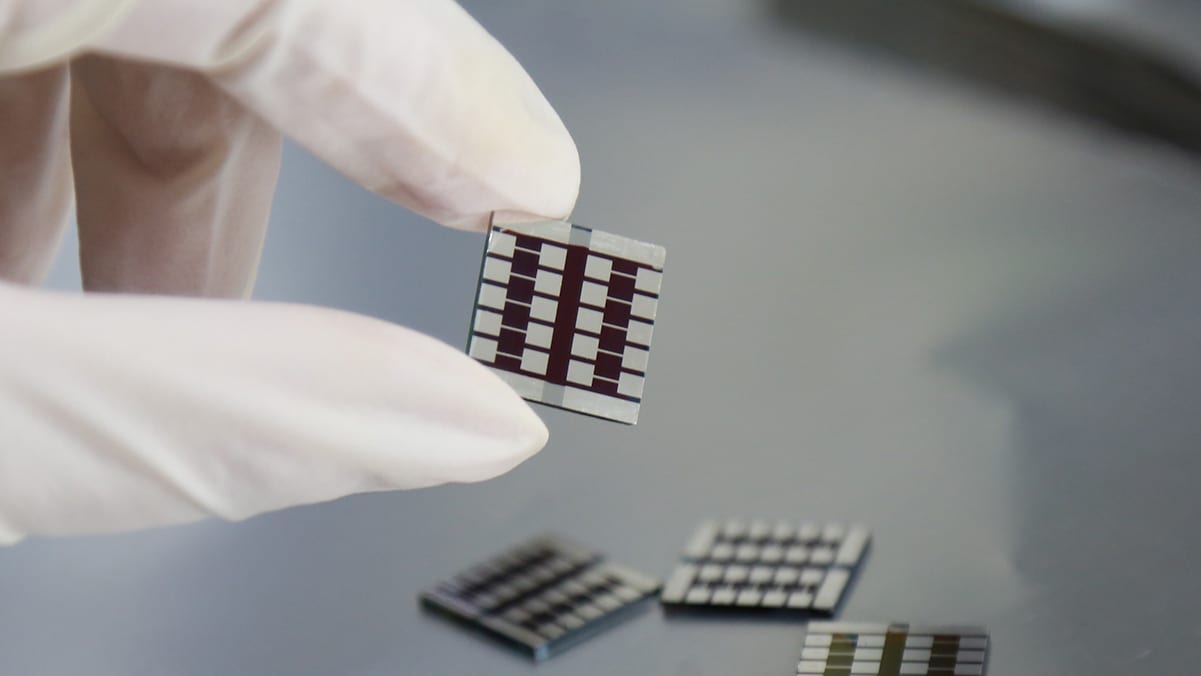

The research indicates that the integration of a graphene layer—a lightweight and highly conductive material derived from graphite—can be seamlessly implemented using roll-to-roll dispersion technology. This manufacturing process is designed to apply additional layers onto flexible substrates, such as solar panels.

According to Halocell, the inclusion of graphene has nearly doubled the efficiency of their solar cells. Paul Moonie, CEO of Halocell Energy, stated that this development has enabled the company to offer a diverse range of low-cost materials suitable for various solar applications.

Funding and Future Prospects

Halocell has secured a three-year grant of $2.03 million from the federal Cooperative Research Centres Projects (CRC-P) to further support its research efforts in partnership with QUT.

In April, a QUT team announced they had set a new efficiency record for perovskite technology, and in July, Dr Minh Tam Hoang from the School of Chemistry and Physics received funding to collaborate with Halocell on addressing the toxicity and instability issues associated with metal halide perovskite materials.

Dr Hoang emphasised the need for improved fabrication processes for next-generation perovskite solar cells to enhance market adoption of commercially viable technologies while minimising production risks. He highlighted that the project aims to develop green-solvent solution processing and perovskite solar cells based on tin instead of lead, making real-world manufacturing cleaner and safer.

Challenges and Market Developments

The perovskite family of solar materials has long been regarded as a promising solution for creating lightweight, flexible solar modules that can be easily applied to various surfaces. They are also cost-effective and can rival the efficiency of traditional silicon-based photovoltaic materials.

However, several challenges have hindered the commercial competitiveness of perovskite solar cells. Key obstacles include the extensive research required to identify the optimal material variations that balance efficiency, cost, and durability, as these cells typically do not last as long as their silicon counterparts.

Despite these challenges, progress is being made. Companies like California’s Caelux are beginning to ship perovskite glass, and Halocell has been selling indoor solar cells in Australia for small electronic devices since last year.

To meet growing demand, Halocell is expanding its manufacturing capacity at its Wagga Wagga plant by adding more roll-to-roll lines, aiming to produce 60 million units annually.